PP Melt-Blown Filter Sediments

If you are in the market for a high-quality filter for your industrial application, you may have come across the term “PP Melt-Blown Filter Sediments.” In this guide, we will provide you with a comprehensive overview of this type of filter, including its uses, benefits, and customization options.

What is PP Melt-Blown Filter Sediments?

PP Melt-Blown Filter Sediments are a type of filter made of polypropylene (PP) fibers that have been melted and blown to form a matrix of fine fibers. This matrix traps and removes particles and sediments from fluids passing through it, making it an essential component in many industrial applications.

How is PP Melt-Blown Filter Sediments Used?

PP Melt-Blown Filter Sediments are used in a wide range of applications, including:

- Water treatment: PP filters are commonly used to filter sediments and other impurities from water before it is used for drinking or other applications.

- Chemical processing: PP filters are used to remove impurities from chemicals and other liquids used in chemical processing.

- Food and beverage processing: PP filters are used to remove impurities from liquids used in food and beverage processing.

- Pharmaceuticals: PP filters are used to filter sediments and other impurities from pharmaceuticals and other medical products.

Benefits of Using PP Melt-Blown Filter Sediments

There are several benefits to using PP Melt-Blown Filter Sediments, including:

- Efficient filtration: PP filters are capable of removing particles and sediments as small as 0.1 microns, making them highly efficient at removing impurities from fluids.

- High flow rate: PP filters have a high flow rate, which means they can process fluids quickly and efficiently.

- Versatility: PP filters can be customized to meet the specific needs of different applications, making them suitable for a wide range of industries.

- Cost-effective: PP filters are relatively inexpensive compared to other types of filters, making them a cost-effective choice for many applications.

Customization Options for PP Melt-Blown Filter Sediments

PP Melt-Blown Filter Sediments can be customized in several ways to meet the specific needs of different applications, including:

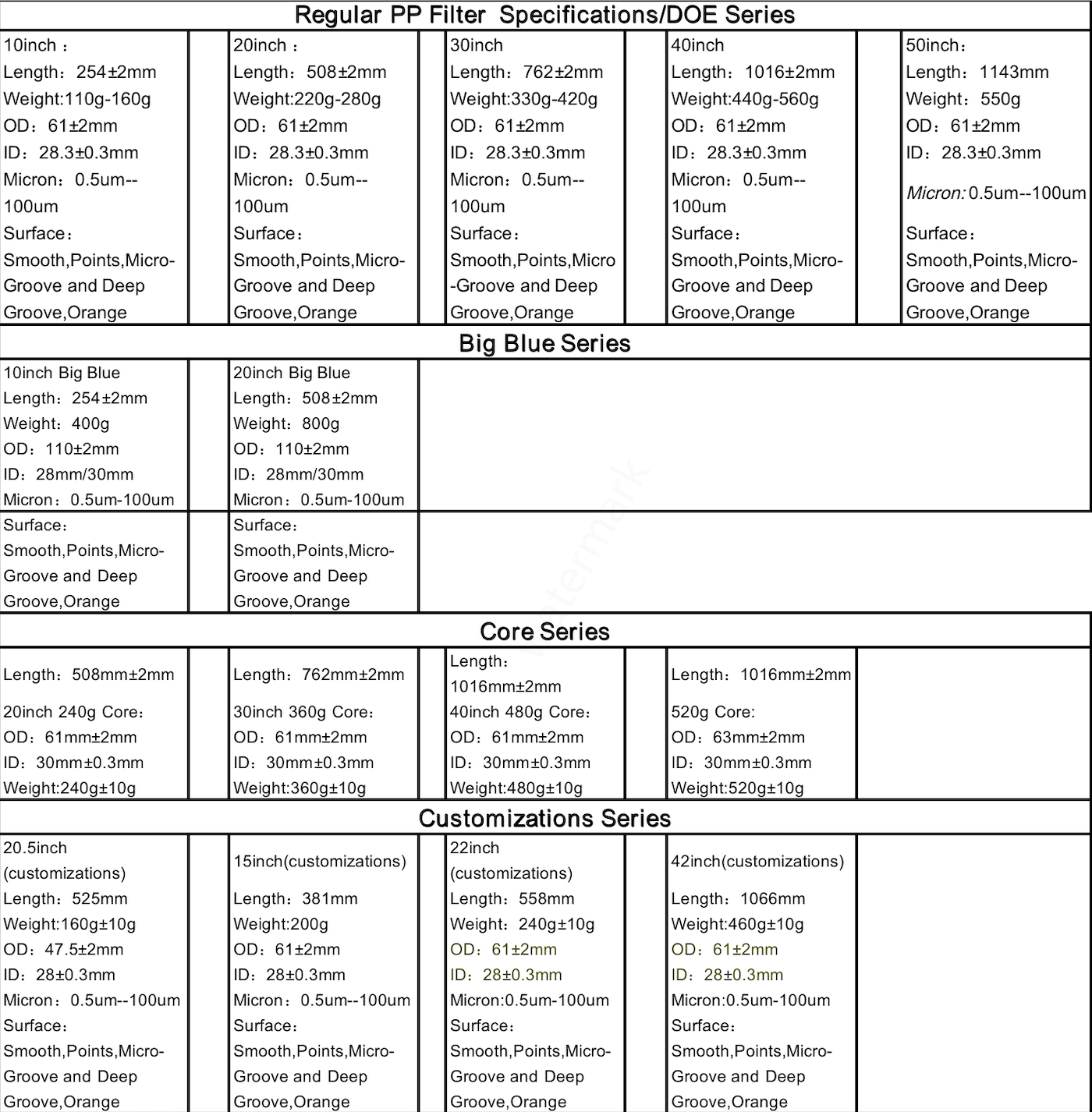

- Size: PP filters are available in sizes ranging from 10″ to 50″.

- Type: PP filters can be DOE (Double Open End) or SOE (Single Open End) type, depending on the application.

- End caps: PP filters can be equipped with different types of end caps, including 222 Flat and Fin end Nitrile O-Ring.

- Surface: PP filters can have micro-groove, deep-groove, or smooth surface depending on the application.

PP Melt-Blown Filter Sediments are a highly efficient and cost-effective solution for filtering sediments and other impurities from fluids in a wide range of applications. By understanding the benefits and customization options of PP filters, you can select the right filter for your specific needs.

SOE and DOE are two common types of industrial cartridge filters used for filtration purposes. The term SOE refers to Single Open End, while DOE stands for Double Open End. These filters can be named based on their type, function, or even after the components used in their construction.

Polypropylene (PP) filter cartridges are a popular choice for filtration applications, and they are available in both SOE and DOE types. An example of a PP filter cartridge is the Melt Blown PP Filter Cartridge, which can be used in both SOE and DOE configurations.

PP filter cartridges are made from high-quality polypropylene materials, which offer excellent chemical and thermal resistance. They are known for their superior dirt holding capacity and filtration efficiency, making them an ideal choice for a wide range of applications.

评价

目前还没有评价